|

|

회사 뉴스

Differences Between Stainless Steel & Copper Alloy Materials in RF Coaxial Connectors such as SMA, SMP, N, 2.92mm, 2.4mm

선술집 시간 : 2025-12-20 16:23:29

>> 뉴스 명부

연락처 세부 사항

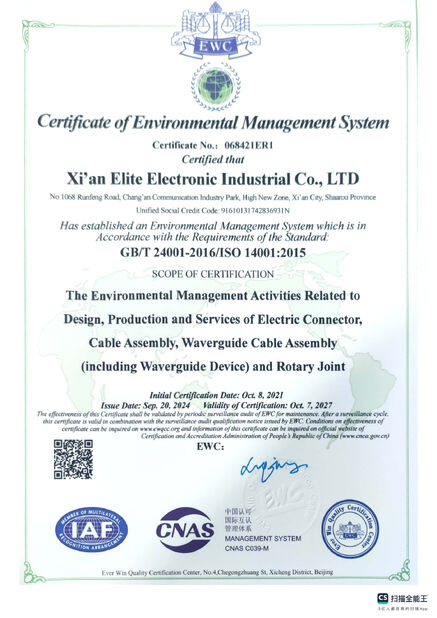

Xi'an Elite Electronics Co., Ltd.

담당자: Ms. Elite

전화 번호: +8613609167652

회사에 직접 문의 보내기